SPRING CLAMPS USER GUIDE

Spring Clamps are used after quality controlled for welding resistance, dentate piece hardness values and tensile strength of the bow and rivets.

Rivets are produced from a special steel material resistance to break off.

Dentated piece’s hardness value is 57-59 HR and in every irrigation operation a report is prepared.

Welding resistance is tested by welding blow test.

MATTERS TO BE CONSIDERED IN USE

Concrete’s specific weight must be calculated and sufficient spring clamp must be used.

(1m3 concrete specific weight is 2000)

Considering the safety factor, the load to one spring clamp should be calculated as MAX 500 Kg.

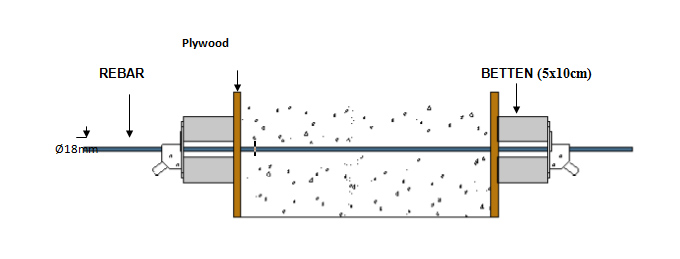

Deformed construction steel is no recommended to fix the mold. Even small probability due to rib it can be scroll and break the hardened dentated piece. If possible use low-carbon soft iron.

The distance between slats placed between spring clamps must be minimum. Otherwise there could be deformation in the spring clamps.

During connecting the mold, spring clamps must be tightened equally and the load must be evenly distributed. Otherwise some molds may be deformed by excessive load.

| © 2012 Nam Demir A.Ş. | Phone: +90 216 364 32 07 Fax: +90 216 314 12 31 |

İmes Sanayi Sitesi E Blok 501/17 Ümraniye - İstanbul / TURKIYE |